Thermal Imaging Mechanical & Electrical Inspections

- Hot Spot Checks

- Switch Board Insurance Inspections

- Infrared Electrical for Insurance

- Distribution Board Inspection

- Overloaded Circuits

- Circuit Board Inspections

- Faulty Terminal Connections

- High & Low Voltage Contacts

- Floor Heating Faults and Mapping

- Damaged Insulation

- Electric Motor Load Balancing

- V Belt Tension

- Cooling Systems

- Hydraulic System Operation

- Alignment of Pumps

- Bearing Problems

- Preventative & Predictive Maintenance

- Infrared Video Maintenance Inspection

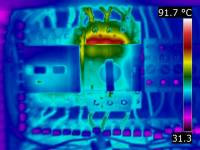

Infrared Thermal Imaging Electrical Switch Board Inspections

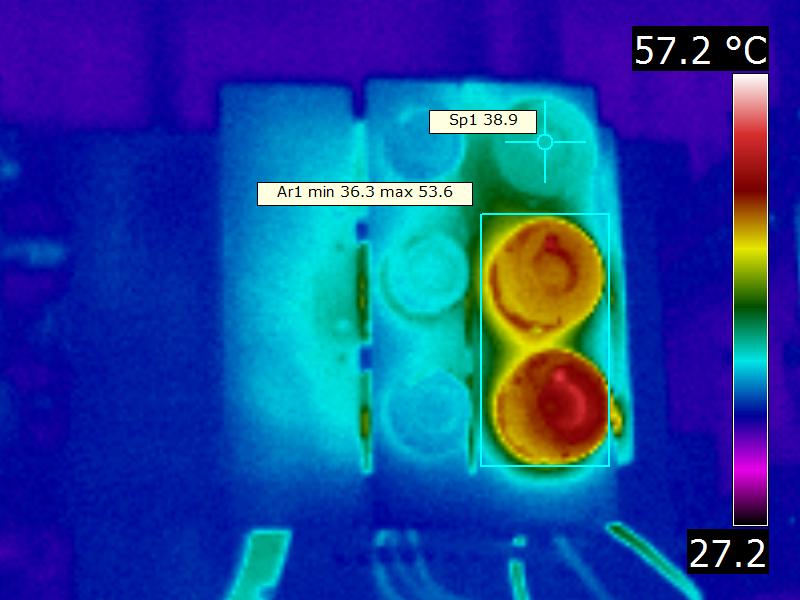

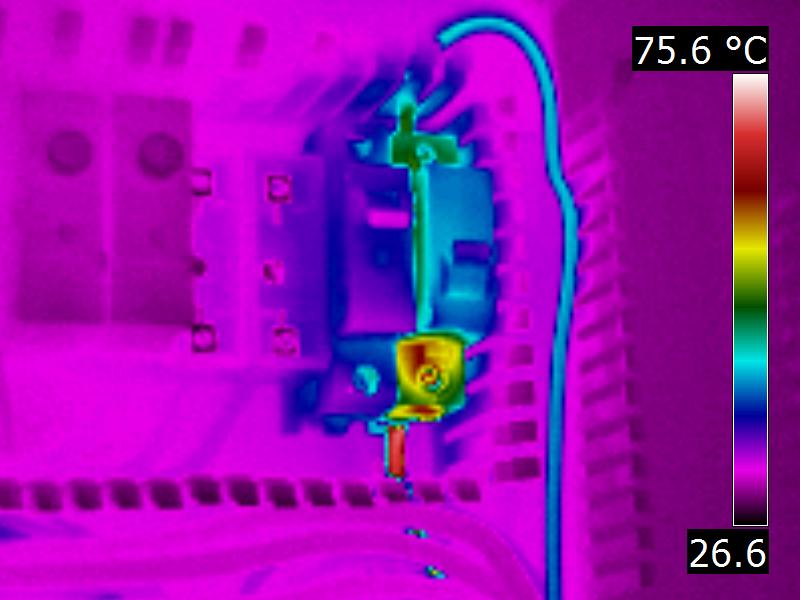

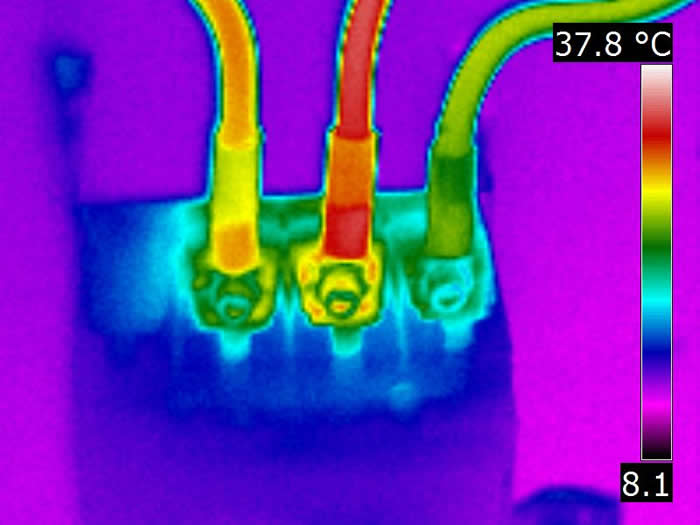

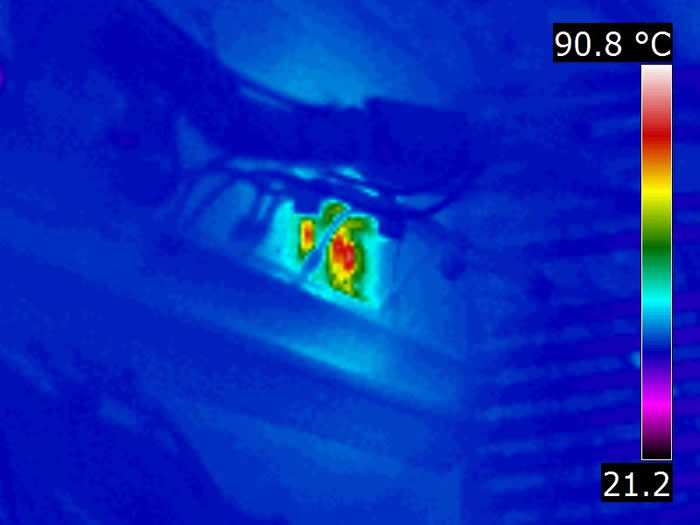

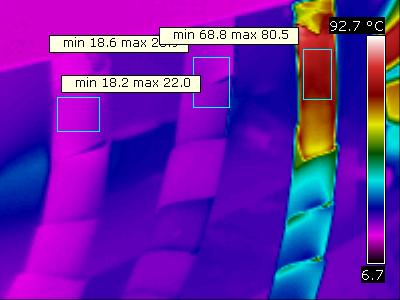

Electrical components get hot before they fail. An Infrared inspection can identify these hot spots because the infrared camera can see heat. Loose or dirty electrical connections, blocked fans and other electrical anomalies cause heat to increase, can cause power outages and sometimes even fires. A thermal imaging inspection of the electrical components can reveal overloaded circuits, load imbalances, faulty and improperly installed components and detect issues before there is a costly outage. The resulting report can be a great aid for business owners, insurance companies and electricians hired to address the identified issues.

Overloaded Fuse

Faulty Electrical Switch

Faulty Connection

3 Phase Load Fault

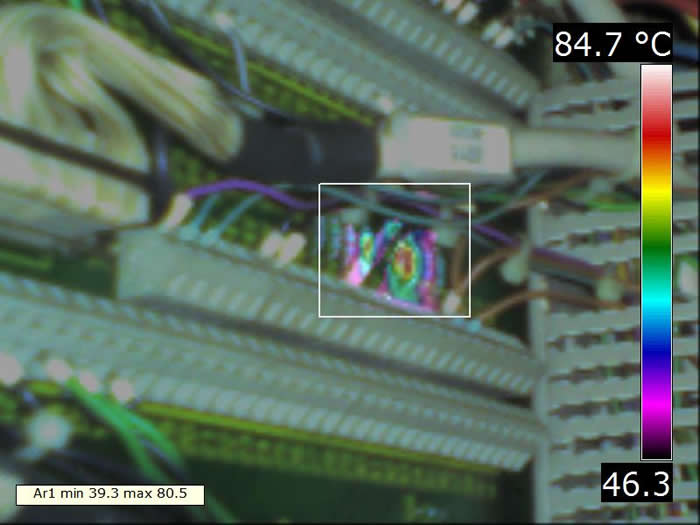

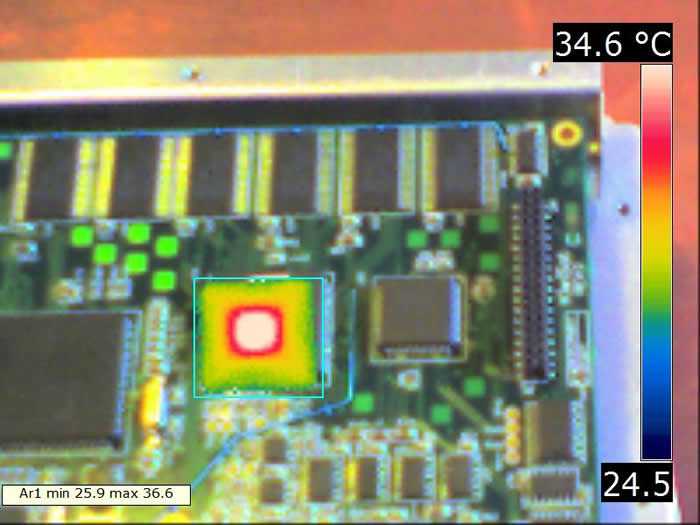

Infrared Thermal Imaging Used To Detect Faulty Circuit Board Components

Electrical components normally run hot when they are faulty. A Thermal Imaging Inspection can often identify these faulty components because the infrared camera can see the heat difference between a normal running component and the hotter running faulty component. A thermal imaging inspection of the electrical components can reveal overloaded circuits, load imbalances, faulty and improperly installed components and detect issues before they fail. The results can be impressive and of great benefit for the technicians hired to address the issues.

Overheating Resistors

Fusion Photo of Resistors

Main Chip Fault

Memory Chip Fault

Infrared Thermal Imaging Mechanical Inspections

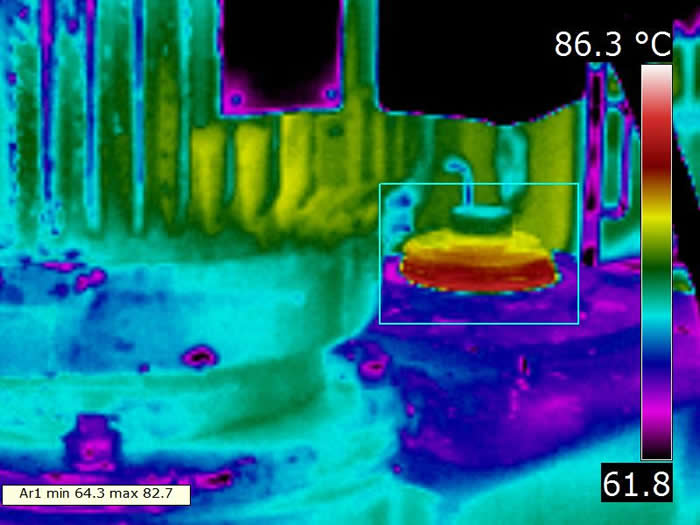

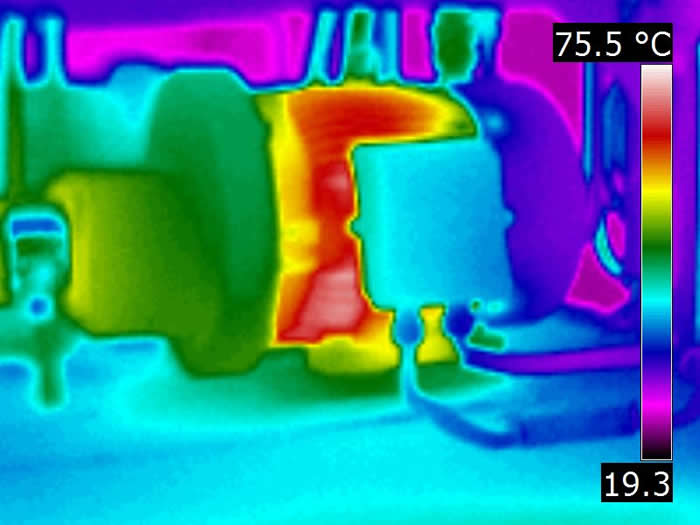

Mechanical inspections often require comparing similar pieces of equipment as well as considering their actual operating temperature. For example, viewed in Infrared, two identical motors operating under the same load should look alike. An impending failure will be evident in the Infrared image. Early detection of a failing component allows for scheduled repairs and avoids costly downtime. Using a Infrared camera with direct temperature readout a Thermographer can show a technician instant temperature results so they can decide whether or not mechanical parts are operating within temperature design tolerances or not.

Overheated Bearing

Roller Friction Fault

Blocked Hydraulic Hose

Overloaded Motor

Commercial Building: Need an Infrared Thermographic Survey for Insurance purposes?

Infrared Building Inspections conduct infrared electrical switch board inspections and compile reports for predictive maintenance and insurance purposes. We inspect electrical control boxes, control panels, electric motors and other equipment on request.

Bearing Heating Problems

Infrared thermal imaging cameras are great for finding overheating bearings, heating problems and alignment issues in motors and machinery as they can be seen instantly in the thermal image. We conduct electrical survey inspections in the North Island of NZ.

Alignment of Pumps

Infrared is great for checking alignment of pumps. Alignment issues can be seen instantly in the thermal image as a hot area.

Infrared Thermal Imaging Scans & Electrical Switchboard Inspections

Detect-A-Leak Ltd Conduct Electrical Switchboard Inspections in the North Island of NZ. We inspect electrical control boxes, switch boards, control panels and other types of electrical components, machinery and equipment as requested. Our FLIR T420 electrical Infrared Camera can read temperatures from -120C to +650C. FLIR electrical camera and specialist reporter software is used to compile reports.

Most insurance companies now require regular independent thermal imaging inspections (by a certified thermographer with a properly detailed report) for commercial buildings, as part of your ongoing insurance cover.

A thermal imaging scan should be conducted every 1 to 3 years (depending on the size and nature of your business or as recommended by your insurance company). We often find once we have completed a Switchboard Inspection for a company they will get us back more often, due to the added benefit of preventative maintenance and early detection of faults that we discover, which can help prevent costly shutdowns due to failure.

For more information on our services contact Detect-A-Leak 0274 338 328.